Chemicals and Services

Cooling Tower Cleaning and Maintenance Services

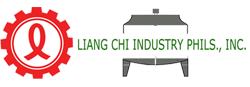

- Open recirculating cooling system designs like cooling tower uses water by recycling it. The tower cools the water for reuse in the process by evaporation. It is the process by which hot water, returning from the process heat exchanger, releases its heat to the atmosphere, is cooled and ready to return back to the process.

Evaporation takes place in the cooling tower. The cooling tower provides the ideal conditions for water to evaporate. The tower breaks the water up into little droplets, thus providing more escape routes for water molecules to evaporate. The rapid flow of air removes evaporated water molecules which allows even more to escape. In the evaporation process, heat energy is removed as the water molecule changes from a liquid to a gas.

- Only pure water can evaporate. No other dissolved solids leave the liquid water. If there are no other water losses from the system, the evaporation process causes an increase in the concentration of dissolved solids in the recirculating cooling water. Each time the increase in the total amount of solids in the tower is equal to the amount of solids already present in the makeup water, this is equal to one cycle of concentration in the tower.

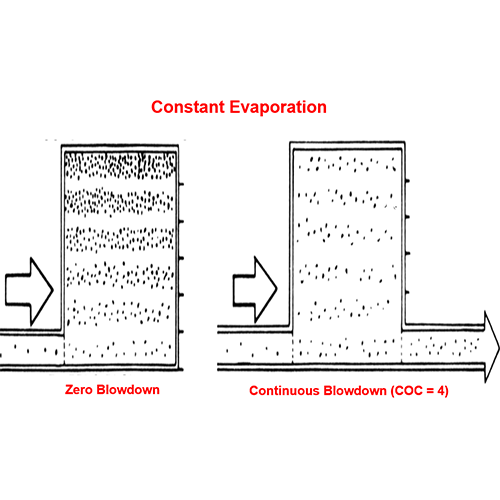

- Each 10oF drop in the water temperature across the cooling tower, results from a 1% loss of cooling water due to evaporation. When this 1% loss of water, occurs, there is a 1% increase in the concentration of dissolved solids in the water. If the cooling water is allowed to continue concentrating without any control, eventually the mineral solids will get so high that scale deposits will occur.Blowdown is the deliberate discharge of water to prevent the dissolved solids concentration in the cooling water from becoming too high, which results in mineral scale. To prevent the dissolved solids concentration in the cooling water from becoming so high that mineral scale deposits begin to form, part of recirculating water is deliberately and continuously dumped from the system. This procedure is called blowdown or bleed-off. This procedure controls the build-up of dissolved solids by replacing the more highly concentrated system water with an equal volume of fresh, less concentrated makeup water.

Aside from evaporation and blowdown, water is also lost in the system due to drift. This accounts to the tower water that is entrained in the exit air, but not including evaporation. Water droplets are carried out of the tower with the induced air. Thus, in order to maintain the nominal flow rate of cooling tower water, make-up water must be added to replace water lost. - Part of Liang Chi’s maintenance service is manual blowdown, but also provides an option for automatic blowdown system using conductivity controller. As an additional line of defence, an automatic pH control system is also offered. Aside from maintaining the cooling tower facilities and ensuring its maximum efficiency, our service technicians also check the condition of auxiliary equipment such as diaphragm dosing pumps and conductivity controllers.

- Cooling towers must be cleaned and maintained for safe operation, while maximizing the cooling efficiency. Regular cleaning service is offered by Liang Chi’s Chemicals and Technical Services Division. Fillers, louvers, water sumps, distribution pans and other wet parts are manually cleaned to remove biological depositions, scaling and fouling. Regular check-ups are conducted to evaluate operating conditions of cooling tower. Our technical team provides counter-measures and troubleshooting to common operating problems such as: noises and vibrations caused by fan blades, power overload for fan blade motors, rise in water temperature, decrease in recirculating flow rate, and excessive water carryover.